Source factory

Heavy-Gauge thermoforming Manufacturer

- All-in-One Thermoforming solutions: from CNC trimming and drilling to surface finishing and all secondary processes.

- Short Lead Times for Prototyping and Production

- Low MOQ(30pcs) For Customization

- Fast Response

ForTOP Delivers Complete Heavy-Gauge Thermoforming Solutions — From Concept to Production — Backed by Over 24 Years of Expertise.

ForTOP Has Several Production Lines, a Tooling Shop, 3-Axis & 5-Axis CNC Machining Centers, and Multiple Thermoforming Production Lines.

A Dedicated Engineer Will Work With You at Every Stage — From Communication and Order Confirmation to Manufacturing and After-Sales Support.

Heavy Gauge Thermoforming

ForTOP specializes in heavy gauge thermoforming (thick sheet vacuum forming), delivering durable, high-quality custom plastic components. With in-house tooling, CNC trimming, and full secondary operations including surface finishes. We offer end-to-end solutions which makes your parts arrive production-ready, with no need for further processing.

What We've Made

The samples shown here represent just a small portion of our capabilities.

Retail Display

ABS Vacuum-Formed Banana Risers For Walmart

Retail Display

ABS Vacuum-Formed Produce Trays for Target

Retail Display

Acrylic Vacuum-Formed Brand Display Signage

Retail Display

Vacuum Formed Insert with Acrylic Panel For Sephora Cosmetic Display

3D Logo Signs

Custom Thermoformed signs with screen printing and LED lighting for Shell Gas Station

LED Logo Signs

Custom Thermoformed auto signs with screen printing, vacuum metallization and LED lighting for PROTON

Machine Housing/Guard

Thermoformed Plastic Robot Shells with Complete Secondary Processing

Machine Housing/Guard

Heavy-Gauge Thermoformed Guard board for Textile Machinery

Recreation & Fitness Equipment

Lightweight,high-impact Thermoformed Plastic Shells for Multirotor Drones

Logistics

Anti-static Thermoformed PS Tray for Electronic Components

Planting & Cultivation

Large-Scale Vacuum-Formed Hydroponic Vegetable Sprout Trays for Greenhouses

Others

Weather-Resistant Clear Acrylic Outdoor Light Cover-Large and thermoformed

Custom Thermoforming Service We Provide

Design For Manufacturing

Early engineering support to ensure your part is functional, manufacturable, and cost-effective. We help avoid design flaws like thinning, poor draft, or trimming issues.

Thermoforming Tooling

We design and build high-precision molds and fixtures tailored to your product’s geometry, volume, and performance needs—ensuring consistent forming results.

Heavy Gauge Thermoforming

Production of large, durable plastic parts using thick sheet materials (1.5–10 mm+), ideal for equipment housings, panels, trays, and industrial enclosures.

CNC Machining

High-precision trimming, drilling, and detailing using 3/5-axis CNC equipment to meet exact tolerances and deliver a perfect fit for assemblies or functional use.

Secondary Processes

We offer finishing operations like bonding, painting, silk-screening, and assembly—so your thermoformed parts are ready for end-use or direct integration.

Full-Process Tracking Service

From design to delivery, we provide full visibility at every stage. You’ll always know your project’s status, with fast response and quality control throughout.

Advantages of Heavy Gauge thermoforming

Heavy gauge thermoforming offers significant advantages over other plastic manufacturing methods like injection molding or fiberglass fabrication.

Cost-Effective Tooling

Thermoforming tooling costs a fraction of injection molding, making it perfect for 100–5,000 parts annually. Aluminum molds deliver fine detail and durability, while affordable prototyping speeds up development.

Strong & Durable

Thermoformed parts deliver excellent impact resistance and structural strength—perfect for tough environments. Materials like ABS, polycarbonate, and HDPE ensure long-lasting performance.

Large-Scale Capability

Heavy gauge thermoforming is ideal for producing seamless plastic parts—up to 10 feet long—in a single piece. Eliminates the need for multi-part assembly, saving time and reducing costs.

Flexible Design Options

Heavy gauge thermoforming supports deep draws, undercuts, and complex shapes.

Choose from a wide range of materials, colors, and textures—and add logos or patterns directly into the mold.

Lightweight & Efficient

Lighter than metal and more efficient than fiberglass, thermoformed parts reduce shipping costs and improve handling ease.

Secondary Processing & Assembly

Thermoformed parts can be post-processed with: 1. CNC trimming for precise dimensions and clean edges; 2. Assembly and integration, including bonding, installation of hardware components, lighting accessories, and other custom fittings; 3. Professional surface finishing, such as electroplating, water transfer printing, UV coating, silk screen printing, hot stamping, and custom painting for a polished final look.

Optional materials

To Meet Your Heavy Gauge Thermoforming Needs,We Work With a Wide Range Of Materials including ABS/PMMA/HIPS/PET-G/ASA/PC…

Customize Your Vacuum Formed Parts

Fully Customizable

Make Your Idea Into Reality

- STEP 1: Initial Consultation we discuss your needs and study your 2D/3D drawings.

- STEP 2: Design Evaluation we analyze the files and proposes the best solution

- STEP 3: 3D Model Confirmation we finalize the 3D model with your approval.

- STEP 4: Mold & Jigs fabrication In-house mold & jigs fabrication begins.

- STEP 5: Sample Production We create and confirm prototypes with you.

- STEP 6: Production Tooling Mass production molds are prepared.

- STEP 7: Trial Run We test and approve pre-production samples.

- STEP 8: Mass Production Complete manufacturing, finishing, assembly,

Customize Your Vacuum Formed Parts

Fully Customizable

Make Your Idea Into Reality

- STEP 1: Initial Consultation we discuss your needs and review your 2D/3D drawings.

- STEP 2: Design Evaluation we analyze the files and proposes the best solution

- STEP 3: 3D Model Confirmation we finalize the 3D model with your approval.

- STEP 4: Mold & Jigs fabrication In-house mold & jigs fabrication begins.

- STEP 5: Sample Production We create and confirm prototypes with you.

- STEP 6: Production Tooling Mass production molds are prepared.

- STEP 7: Trial Run We test and approve pre-production samples.

- STEP 8: Mass Production Complete manufacturing, finishing, assembly,

What Makes Us the Right Partner

- Complete thermoforming solutions — from CNC trimming and drilling to surface finishing and all secondary processes.

-

- In-house tooling, advanced equipment, and decades of expertise ensure quick samples(with 2 weeks) and fast production(3-5weeks) you can count on.

-

- backed by 24 years of industry expertise, a full range of in-house equipment, multiple forming lines, and comprehensive secondary process lines.

-

- Source Factory-Direct Pricing

- Rapid Samples with Dedicated In-House Team

- In-House tooling Shop — Faster Turnaround, Full Control

- Responsive Sales & Support Team

What Makes Us the Right Partner

- Complete thermoforming solutions — from CNC trimming and drilling to surface finishing and all secondary processes.

-

- In-house tooling, advanced equipments, and 24-year expertise ensure quick samples(with 2 weeks) and fast production(3-5weeks) you can count on.

-

- backed by 24 years of industry expertise, a full range of in-house equipment, multiple forming lines, and comprehensive secondary process lines.

-

- Source thermoforming manufacturer-Direct Pricing

- Rapid Samples with Dedicated In-House Team

- In-House Tooling Shop — Faster Turnaround, Full Control

- Responsive Sales & Support Team

WHO ARE WE

About ForTOP

Since 2001, Fortop Manufacturing Co., Ltd., based in Guangdong, China, has been a trusted name in custom heavy-gauge thermoforming. Backed by 24+ years of experience and a 10,000 m² advanced facility with 3-axis & 5-axis CNC machining, in-house tooling, multiple forming lines, and full secondary process lines, we deliver precision thermoformed plastic parts designed to meet the unique needs of customers across the globe.

Our thermoformed products are widely used in retail displays, equipment guards, device enclosures, the planting & cultivation industry, and infrastructure engineering. We proudly support end users like Walmart, Target and Sephora, and provide custom heavy gauge thermoforming parts with complete secondary services for retail displays, LED Logo Signs, industrial equipment and specialty enclosures.

Over 50% of our output is exported to the U.S.. We’re ready to work with you — as your trusted, responsive, and long-term partner in custom heavy gauge thermoforming. Let’s build something great—together!

WHO ARE WE

About ForTOP

Since 2001, Fortop Manufacturing Co., Ltd., based in Guangdong, China, has been a trusted name in custom heavy-gauge thermoforming. Backed by 24+ years of experience and a 10,000 m² advanced facility with 3-axis & 5-axis CNC machining, in-house tooling, multiple forming lines, and full secondary process lines, we deliver precision thermoformed plastic parts designed to meet the unique needs of customers across the globe.

Our thermoformed products are widely used in retail displays, equipment guards, device enclosures, the planting & cultivation industry, and infrastructure engineering. We proudly support end users like Walmart, Target and Sephora, and provide custom heavy gauge thermoforming parts with complete secondary services for retail displays, LED Logo Signs, industrial equipment and specialty enclosures.

Over 60% of our output is exported to the U.S.. We’re ready to work with you — as your trusted, responsive, and long-term partner in custom heavy gauge thermoforming. Let’s build something great—together!

OUR TEAM

Teamwork Makes the Dream Work

- General Manager

- Gu Zai

- Combining strategic vision with hands-on leadership to deliver high-quality custom thermoforming solutions worldwide.

- Sales Manager

- Shirley Fu

- Driving customer success with tailored solutions, responsive service, and a deep understanding of custom needs.

- Account Manager

- Michelle Yang

- Ensuring smooth communication, fast responses, and seamless project coordination from inquiry to delivery.

- Head of MFG

- Leo Yuan

- Overseeing day-to-day production with a focus on quality, efficiency & delivery timelines,with 25-year industry experience.

- Chief Engineer

- Dave Zhang

- Turning ideas into Reality with speed, accuracy, professions and 15-year industry experience.

- General Manager

- Gu Zai

- Combining strategic vision with hands-on leadership to deliver high-quality custom thermoforming solutions worldwide.

- Sales Manager

- Shirley Fu

- Driving customer success with tailored solutions, responsive service, and a deep understanding of custom needs.

- Account Manager

- Michelle Yang

- Ensuring smooth communication, fast responses, and seamless project coordination from inquiry to delivery.

- Head of MFG

- Leo Yuan

- Overseeing day-to-day production with a focus on quality, efficiency & delivery timelines,with 25-year industry experience.

- Chief Engineer

- Dave Zhang

- Turning ideas into Reality with speed, accuracy, professions and 15-year industry experience.

Common Questions

Most Popular Questions

We have listed some questions you may ask. If you have more inquiries about our services, you can send an inquiry to contact us.

Thermoforming offers great versatility for product design and works well with several materials. The material used for a thermoforming project will be determined by the product’s intended use and additional industry-specific regulatory considerations. We mainly focus on ABS/PMMA/HIPS/PET-G/PC/Acrylic……

Absolutely! You can choose the size, type of plastics materials, and even the color and surface texture. Just send us your drawing for checking first.

No worries — our engineering team will review your design and recommend the most suitable material based on your product’s application, strength requirements, and budget. We’ll also evaluate the feasibility and suggest improvements if needed, ensuring your project is both practical and cost-effective.

Our typical lead time is 2–5 weeks, depending on the complexity of the project and order volume. For urgent needs, we also offer expedited services — just let us know your timeline!

Yes — we’re built for it. Small batch prototyping is one of our strengths. It helps you move faster, test smarter, and reduce risk before scaling up.

We typically produce prototypes within 2 weeks, depending on the complexity and material requirements. With our in-house mold shop and rapid tooling capabilities, we help you validate your concept quickly and efficiently.

Customer Success Cases

Supplying TARGET with Quality Plastic Produce Trays

In 2020, during the COVID-19 pandemic, Target urgently needed ABS Vacuum-Formed produce trays as their supplier fell short on quality and cost. After careful evaluation, they turned to ForTOP.

With only sample trays, we quickly refined the design, completed prototyping, and started mass production. Despite logistics challenges, we ensured timely delivery through efficient coordination.

Today, ForTOP delivers over 30 x 40’GP containers of produce racks with ABS trays to Target each year.

Earning Walmart‘s Trust with Quality and Speed

Following our successful partnership with Target, Walmart USA approached ForTOP in 2021 for custom plastic thermoforming components. We quickly completed prototyping and testing, and began supplying improved banana displays and lidded tubs.

Thanks to our consistent quality and responsive service, Walmart has placed repeat orders ever since. Even in early 2025, amid rising tariffs and market uncertainty, they continued ordering from ForTOP—while many competitors paused production, our factory stayed in full operation.

Golf Cart Parts Manufacturing for a Mexican Client

A Mexican company specializing in the assembly of golf carts partnered with ForTOP to source high-quality plastic components. Their senior management visited China twice in search of a reliable manufacturing partner.

In 2023, they connected with ForTOP and conducted an on-site audit. Impressed by the production quality and parts ready to ship to the U.S. and Saudi Arabia, their confidence grew significantly. Today, ForTOP manufactures 200 sets of golf cart components monthly for the client, with regular shipments delivered by sea to Mexico.

After Exploring China, They Came Back to ForTOP

A Mexico-based company specializing in plastic components for Jeep vehicles explored multiple manufacturers across China in search of the right partner. After extensive comparisons, they ultimately returned to ForTOP.

During the collaboration, ForTOP approached the project from the customer’s perspective, leveraging strong design capabilities to optimize several production processes. As a result, mold production costs were reduced by 5%–10%, and the strength performance of the products improved across multiple metrics. The improvements earned high recognition and praise from the Mexican client.

Customized Police Vehicle Seats for a Dubai Client

In October 2019, a Dubai-based company specializing in police vehicle modifications contacted ForTOP through a referral from a U.S. industry peer. After in-depth phone discussions, they placed an order for custom detention van seats based only on general dimensions.

ForTOP quickly responded, iterating through multiple design rounds and delivering three sample seat options for the client’s executive team to review. Once approved, full-scale production began immediately. To this day, ForTOP continues to supply over 60 sets of these custom seats to Dubai every month via sea shipment.

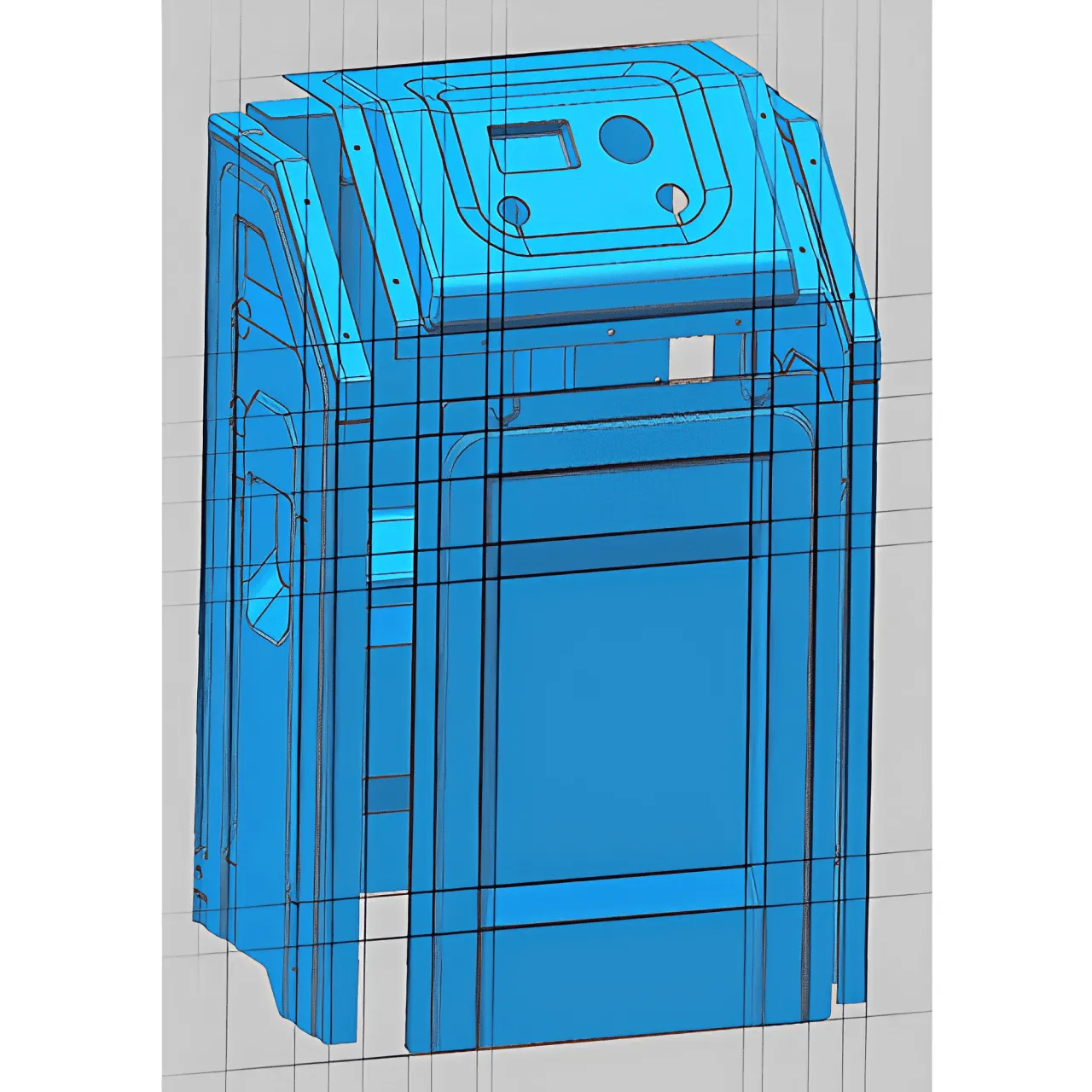

Precision-Made Enclosures for Smart Logistics Robots

In November 2023, a leading Shenzhen tech company specializing in smart warehouse transfer robots chose ForTOP as their manufacturing partner after a thorough evaluation of our equipment, production capacity, and technical expertise.

Working from the client’s original drawings, ForTOP proposed optimized manufacturing and assembly solutions, earning strong client approval. Since early 2024, we’ve been producing approximately 1,000 high-quality enclosures per month, with products shipped to multiple international markets.

No risks, just results.

We back every project with a

full refund guarantee.

Backed by in-house capabilities, hands-on experience, and a commitment to your deadlines and goals.

Phone: +86 18925329050

sales@fortopmade.com

info@fortopmade.com

No risks, just results. We back every project with a full refund guarantee.

Backed by in-house capabilities, hands-on experience, and a commitment to your deadlines and goals.

Phone: +86 18925329050

sales@fortopmade.com

info@fortopmade.com